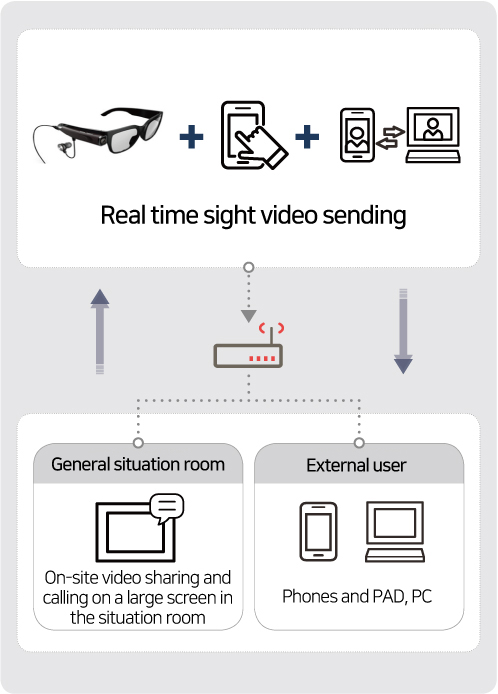

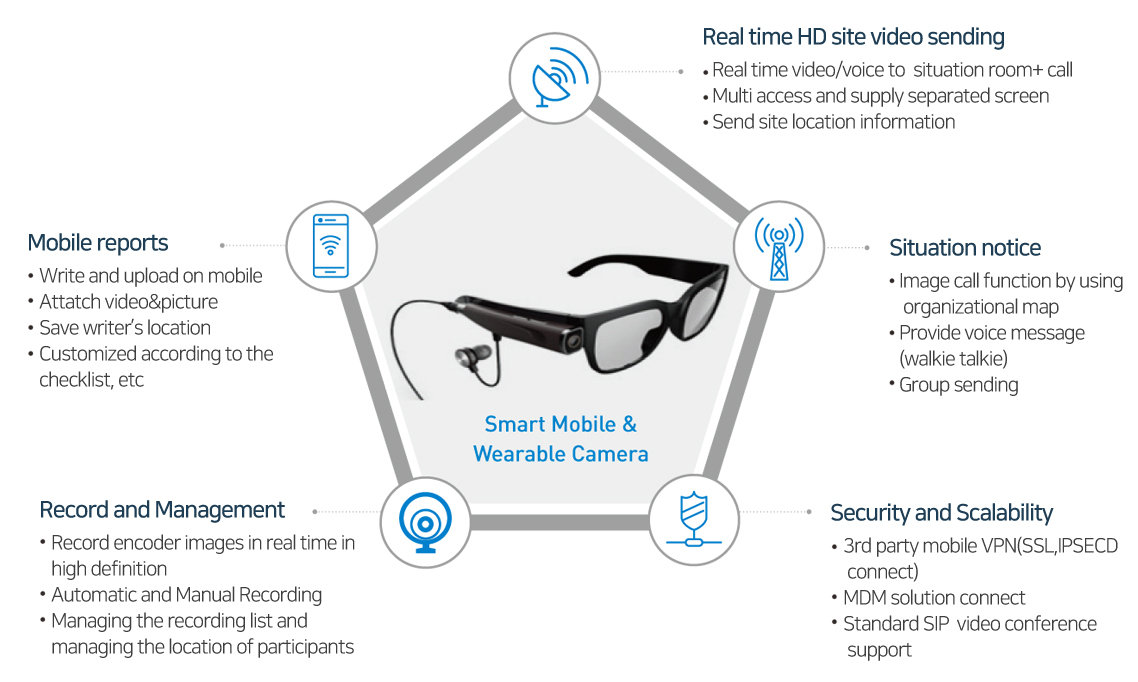

Mobile Monitoring Safety Maintenance System

Smart Mobile & Wearable Camera

- A system that enables video calls (over 1 : 5 calls) by establishing a control center in the office and providing portable devices to third party (operator, disaster prevention officer, ordering person, etc.)

- Establish a communication network that combines wearable and mobile phones

- Rapid notice and real-time site command and support

- Recording and Field Reports/ Multi Connections / Sharing Location Information

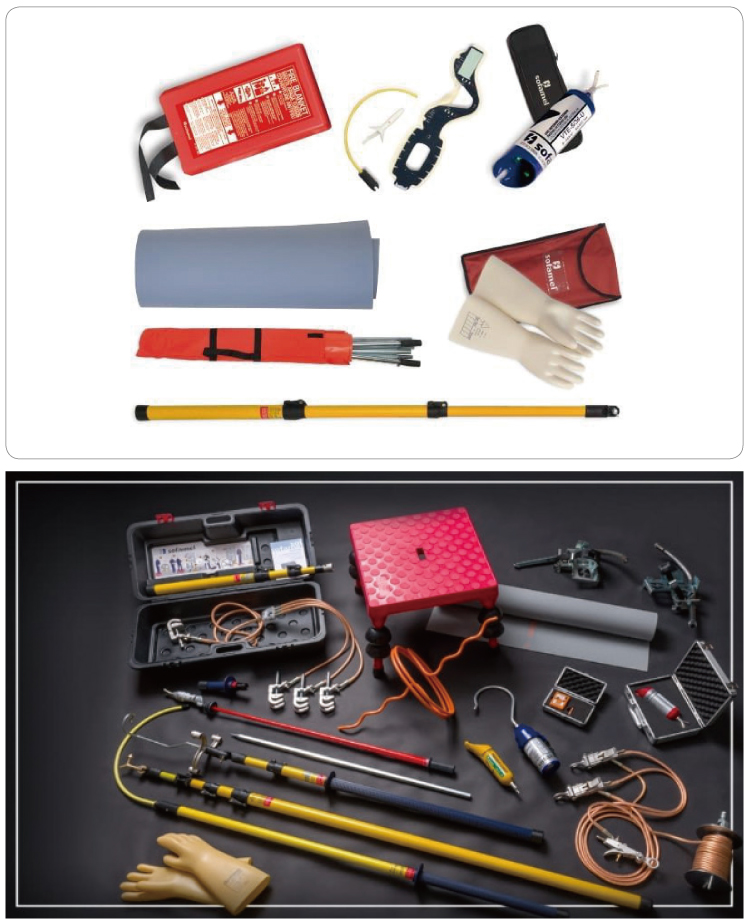

Safety, protection material (Customize)

- A rescue kit for emergency rescue of the demanders for electrical safety accidents.

- first aid kit `Visual & Acoustic Detector

- Insulating armor

- Insulated leather gloves

- Insulated rubber mat

- Insulating stick

- Structural hook and neck retainer

- Structural stretcher

- Fireproof blanket

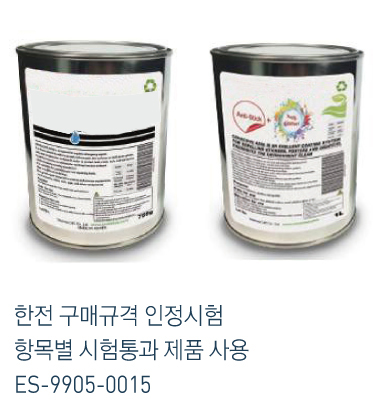

Paint & Varnish

Ground utilities paint & vanish

Selected by KEPCO for paint & varnish product of utilities (ES-9905-0015)

- Coating the ground utilities with special designed paint to prevent putting ads, graffiti, etc.

- Easy installation

- Reasonable price

- Eco-friendly

- Clear coating color

- Insulation & UV prevention

- Reducing the cleaning cost

- Suggesting fine view of the city utilities

- Protects the origin color of the object with clear color paint

Rapping band installation

- Nonwoven outer material, can be painted.

- No damage on the object, maintains over 30years

- Optimal for facility maintenance and life extension of various materials

Electric Asset Cleaning

- Continued exposure to dust and air pollutants has led to short circuits caused by the occurrence of tracking between charging anodes in the facility, resulting in a fire.

- 친환경 원료의 세척제를 사용하여 미세 먼지들 불순물 완전세척 활선상태에서 작업이 가능하여 효율적이며 비용절감 가능

- Anti-static cleaning

- Disassemble cleaning

- Technical precision cleaning

- Eco-friendly cleaning (non-toxic)

- Improve equipment efficiency

- Increase Productivity

- disability prevention

- prevention of malfunction

- Increase work efficiency

- Anti-static cleaning

- Disassemble cleaning

- Technical precision cleaning

- Eco-friendly cleaning (non-toxic)

- Improve equipment efficiency

- Increase Productivity

- disability prevention

- prevention of malfunction

- Increase work efficiency

flame retardant nonconductive

safety cleaning

- Cleaning without power cut off

- Perform safe and rapid cleaning to minimize inconvenience to customers

Prevention of malfunctions

caused by fine dust

- Precision washable to fine parts of various circuit boards and wiring.

- Eliminate equipment-related safety accidents and malfunctioning elements

Equipment protection and life extension

- No damage to equipment by using insulation cleaning products and specialized equipment

- Extend the life of equipment and improve performance by preventing accidents and malfunctions

Complete cleaning of internal fine dust

- 절Complete cleaning of all fine dust and impurities by insulating cleaning products

- Complete cleaning by world-recognized insulation cleaning products and electrical specialists

eco-friendly cleaning

- Provide eco-friendly cleaning with non-destructive components of the ozone layer

- Safe working environment and specialized cleaning work machines with natural citrus scents

- Cleaner impurities filtering

- Washing products Water Detection Detachment

- Filtering impurities in cleaning air

- Water Detection Detachment of Cleaning Air

- Detection of leakage current in the washing asset

- Corona detection, fire prevention

- Prevent workers from electrical shock and ground accidents

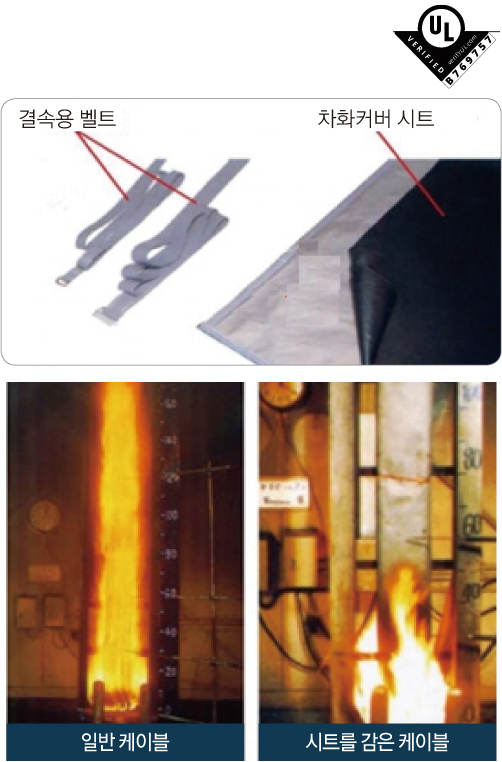

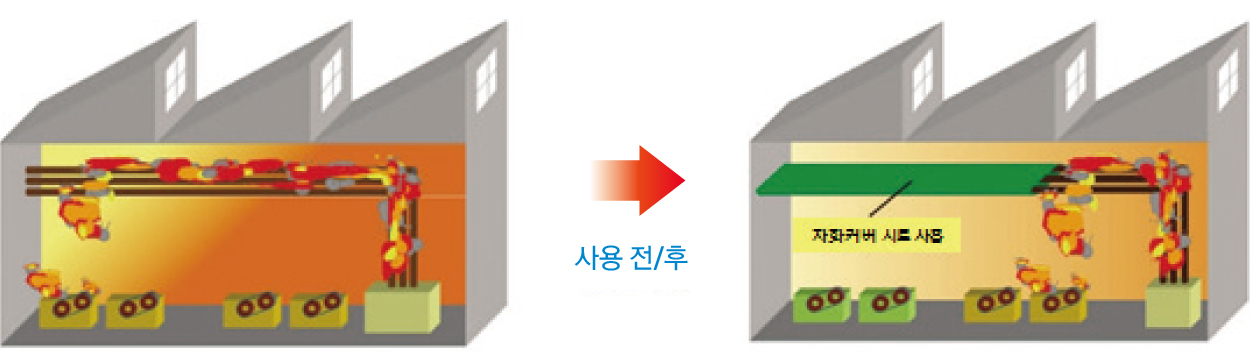

Cable combustion-resistant sheet installation

Manhole surrounding asphalt improvement & repair

Workability

Complete by winding the seat and securing it with a belt, etc.

Compared to the prevention of combustion by coating, the installation time can be greatly reduced.

Also, it can be rewounded repeatedly or separated, which can increase efficiency in removing and re-wireing cables, etc.

Compared to the prevention of combustion by coating, the installation time can be greatly reduced.

Also, it can be rewounded repeatedly or separated, which can increase efficiency in removing and re-wireing cables, etc.

Combustion protection

IEEE std383-'74 compliant [vertical tray test] (815°C heating X 20 minutes).

Environmental response

The amount of hydrogen halide produced during combustion is less than 5mg/g, and there are few corrosive gases, etc.

Deterioration prevention

It denies mold production and is suitable for mold-prone areas such as power asset. Also, we are fully responding to deterioration of water resistance, oil resistance, and drug resistance.